Carmina account required to add an item to your wishlist

Create account now

1

CREATING THE LAST

Carmina has a collection of over 200 different lasts, both in our archives as in the making.

2

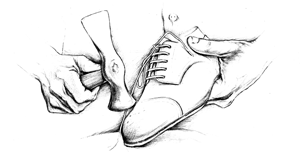

CREATING AND TRACING THE PATTERN

Our artisans draw the model directly onto the wooden last

3

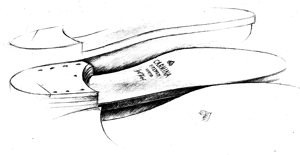

CREATING THE PATTERN PIECES

The lines traced on the last in three dimensions are tessellated onto pattern pieces with which we can then click the leather.

4

SELECTING THE MATERIAL

We have a regular stock of over 18000 leather hides in our factory. All of them are sourced from the best tanneries to ensure the highest possible quality.

5

CLICKING

Once the material has been selected, our artisans cut by hand all the leather parts.

DISCOVER OUR LASTS, LEATHERS AND SOLES

Carmina manufactures handmade shoes of the highest quality since 1866.